This article is intended to provide a brief overview and methodology of the application of Current Injection Testing to earthing system assessment.

For a general description and introduction to earthing, read the Introduction To Electrical Earthing article.

For a guide to applying the most appropriate testing methodology to assess your earthing system read the Application Guide to Earthing System Testing.

An earthing system is any system intended to carry fault current back to the source, and commonly consists of electrodes and buried grid in contact with the soil, and also includes overhead earth wires, cables screens, connected metallic objects, and the soil itself.

When the current enters the buried earthing system, there is a resultant voltage rise, known as an Earth Potential Rise (EPR). Differences in potential between the soil and metallic objects mean that someone coming in contact with any metallic objects at the same time a fault occurs, may be subject to a voltage difference across their body.

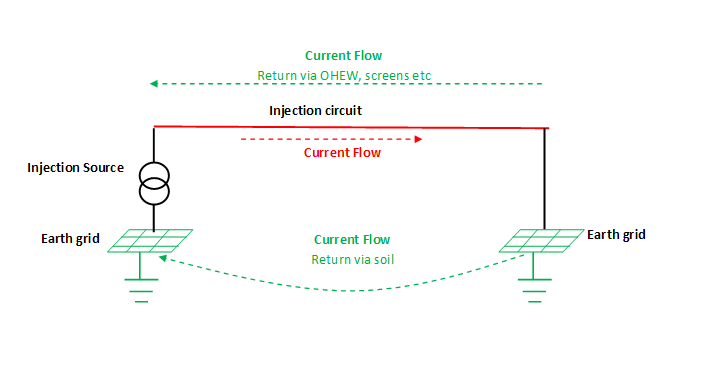

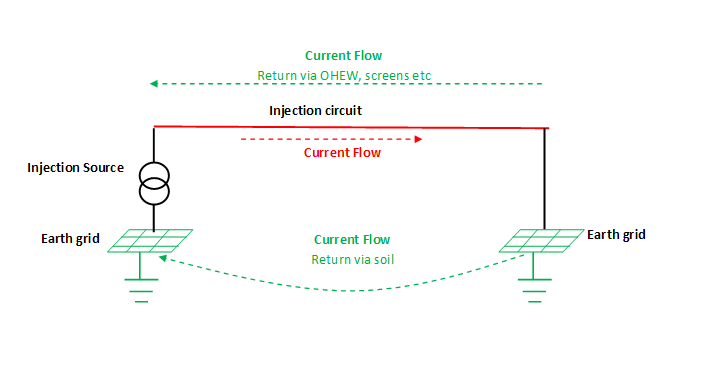

Current injection testing is used to simulate a single phase to earth fault by injecting a low power, off frequency current into the earthing system. Provided the injection circuit used is the same or similar to the actual fault circuit, it enables real world voltages and currents to be measured, albeit at scaled down magnitudes.

Earthing Assessment Aims

There are a number of aims that may be necessary or desirable to achieve, including:

- Inspection of earth grid elements and bonding

- Confirmation of bonding and continuity of earth grid elements

- Measurement of earthing system impedance

- Measurement of earth grid resistance

- Measurement of Earth Potential Rise

- Voltage hazards measurement and compliance (such as step, touch and transfer voltages)

- Current distribution measurements and confirmation of the performance of auxiliary paths (such as earth wires and cable screens)

And in general confirming any assumptions and analysis used in design, and assessing compliance to relevant standards.

The Fault Circuit

In order to ensure the simulated voltages and current are directly comparable with the fault scenario under consideration, the circuit used to inject current must closely match the fault circuit, or that any sources of error are known and can be quantified. Ideally, the actually fault circuit should be used – this typically means injecting current over an out of service feeder between the fault location and the supplying substation. The figure below shows a typical current injection circuit.

There are two common circuits utilised in current injection testing:

- Using an out of service feeder

- Using a temporary cable and electrodes

The feeder is the first choice as it represents the actual fault scenario. When testing over a feeder, an outage is required. Typically a test will take 6-8 hours, and as such an outage is required over a whole day, ideally with the switching completed the evening prior or early on the morning of the test. The following procedure describes the switching and testing using an overhead feeder, but the principles generally apply to cables and to temporary circuits as well.

Typical Testing Day

- Arrive on site, identify hazards and complete safety documentation, sign on to feeder outage etc, undertake inductions

- Hazards to look for:

- UGOH’s, pole earths, pipelines and test points, fences and transfer hazards, nearby MEN, bonding arrangements (screens etc), comms pits

- Set up equipment, run out remote lead/prepare feeder for test

- Conduct visual inspection of earth grid and bonding as well as DC continuity (often while feeder outage is prepared or lead run out)

- Start injecting current, calibrate meters (voltage and current)

- Measure current paths

- Measure EPR

- Measure touch voltages

- Optional:

- EPR off remote grid

- Frequency sweep

- Soil resistivity test

Zero Sequence Earthing is happy to provide advice and assistance with carrying out earthing system assessment using Current Injection Testing or other methods that may be applicable.

Zero Sequence Earthing

(02) 4039 8000 / 0434 190 272

2 thoughts on “Current Injection Testing for Earthing and Grounding Assessment”